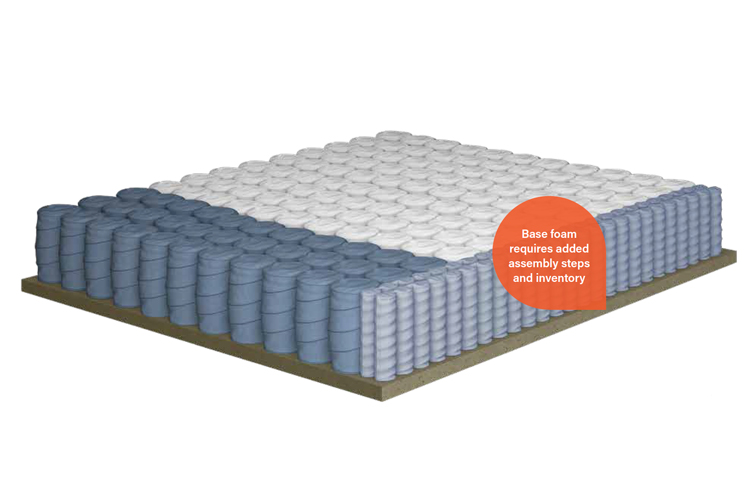

Illustration enhanced to show details.

More value with fewer resources

Ditch the non-value-added commodity foams and save time, resources, waste, storage, and chemical use. Switch to Quantum Edge® or Caliber Edge® with Eco-Base® innersprings without changing your mattress profile.

The current way of applying base foam and foam encasement in mattress construction is inefficient. Instead of using commodity foams that add little value to the consumer, go with Eco-Base®-equipped, performance edge innersprings. Retain your mattress profile – save production time and labor, reduce SKU’s and resources, and provide a “sustainable” story for your products and brand.

Traditional mattress building

Stop using unneeded, wasteful steps in building your mattresses. These steps require base foam, as well as flipping, gluing, and a lot more. Eco-Base® comes ready-to-build, which saves you time, resources, and money.

The added value of less commodity foam

Non-value-added commodity foam is a waste, in more ways than one. It may pad your mattress profile, but how long before it degrades? Eco-Base® springs deliver active, vibrant comfort throughout the entire mattress that works well with high-quality, specialty comfort foams. In addition, springs won't break down and Eco-Base® delivers superior shape retention – both in the build process and through the roll-pack cycle.

Technical aspects of Eco-Base®

Springs deliver responsive comfort, while commodity foam only adds structure. By efficiently utilizing spring wire, we ensure higher performance edges and enhanced durability, all while maintaining the mattress profile through a streamlined manufacturing process.

Materials reduction

Ditching the non-value-added commodity foam will save you a lot. Eco-Base® innersprings come ready-to-build, as well as ready to finish and cover. That will save on wasteful materials such as adhesives and the labor needed for the pre-build process. You'll also eliminate all that wasteful foam crowding up your warehouse.

Sustainability

Offer a sustainable option – and tell your customers about it. By using springs instead of commodity foams that will ultimately degrade, Eco-Base® reduces chemical usage by 80% per unit.* That’s a sustainability story you can leverage.

*Comparing 660 CPE 6” with base foam to 660 CPE 7” with Eco-Base®, 682 CPE 8” with base foam to 736 CPE 9” with Eco-Base®, and 789 QPE 8” with base foam to 800 QPE 9” with Eco-Base®. Base foam comparison is 1.0” 1.8 lb commodity poly base foam in 60” x 80” size.