Innersprings

Leggett & Platt is the worldwide leader in developing and producing innerspring technology. Offering a unique blend of comfort and durability, innersprings are the most popular sleep core in the United States.

At Leggett & Platt, we produce a wide range of open coil and fabric-encased innerspring units including our popular family of ComfortCore® and our growing line of ActivEdge™ steel perimeter products.

Benefits of Innersprings

There's an art and science to turning steel into the most popular sleep core on the market. While the process is fascinating and complex, what matters is that people get a good night's sleep. Innersprings offer a unique blend of comfort and durability that delivers blissful rest, night after night.

Comfort

Innersprings with Leggett & Platt’s Active Support Technology® respond to the individual contours of a sleeper’s body. Infinite pressure relief means your body will sag. When sinking occurs, your body loses proper spinal alignment, which can lead to muscles tensing and fighting for a stable position. Support is a critical factor in finding a relaxed position that leads to deep sleep.

Durability

Your mattress should feel the same way every day. It’s well known in the mattress industry that cheap foams break down and lead to body impressions. Leggett & Platt innersprings are tested for durability because we want people to enjoy consistent sleep. Mattresses packed with low-density foam and other cheap materials often do not last. Leggett & Platt is tenacious with internal testing and has monitored the results of millions of units being sold and used in the real world. All that testing and caring about our quality means we can prove our products are durable and deliver great sleep, night after night.

Also, we’ve been roll-packing our products for years and have proven the bounce-back characteristics of our innersprings. If you’re building beds for shippable e-commerce programs, we have durable, comfortable components that are roll-pack ready.

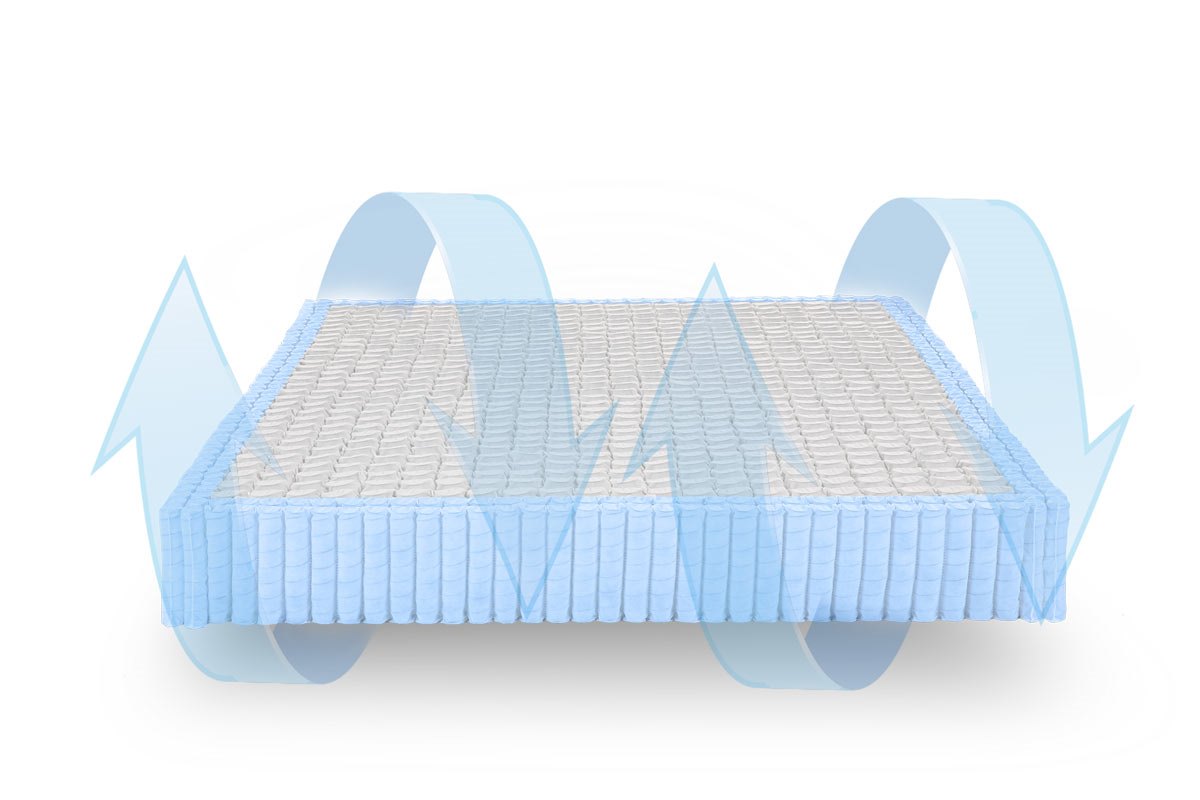

Cooler

Look at springs and then look at foam. Which do you think sleeps cooler? Innersprings are open to the air, whereas foam is a lock-cell material that traps heat. The Kansas State University Environmental sciences lab has even shown that innersprings transfer heat up to 28% more efficiently than all foam products. Gimmicks might create an initial cooling effect, but innersprings are proven to more efficiently move heat away from a sleeper.

Types of Innersprings

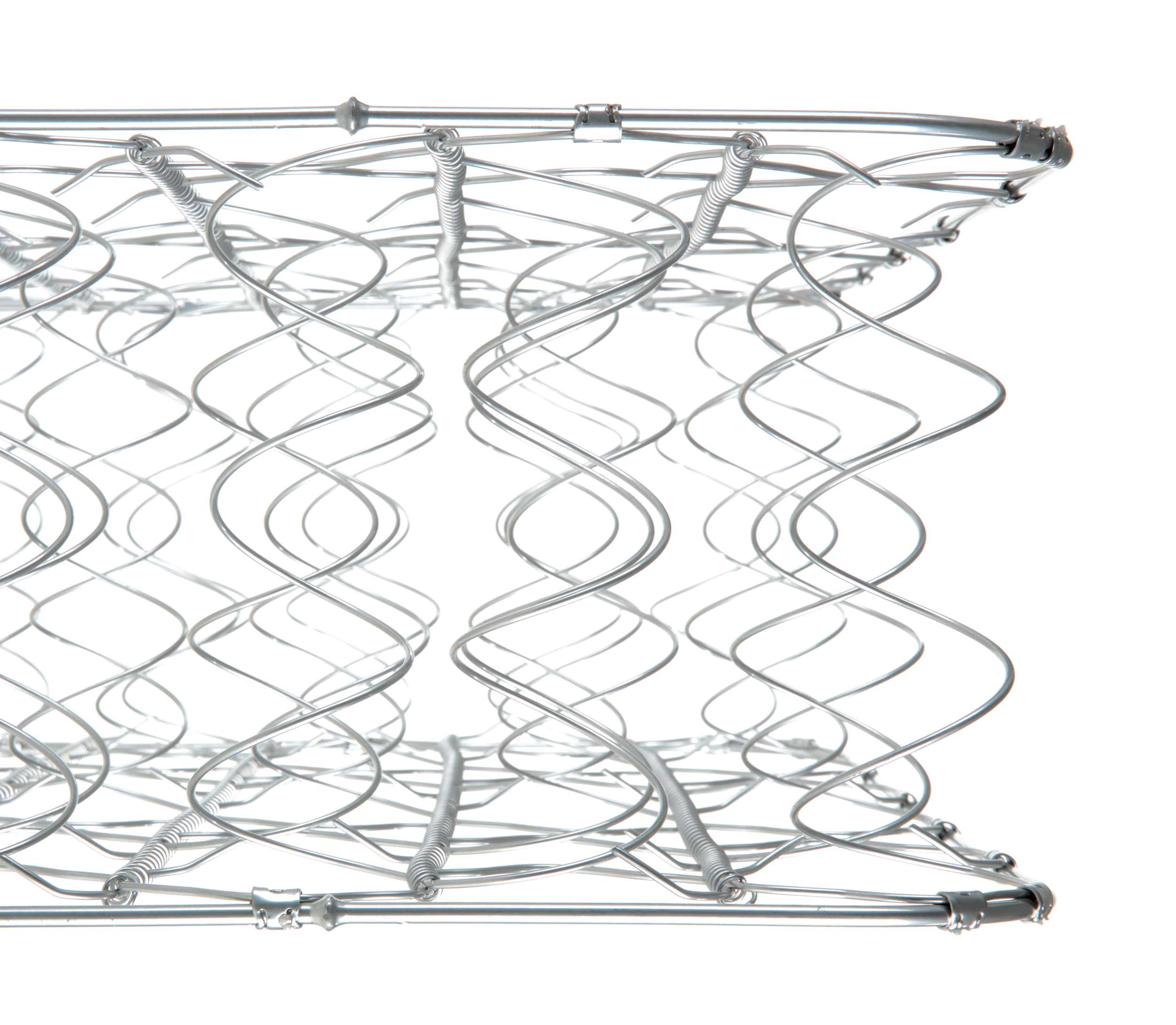

There are two major types of innersprings: open coil and fabric-encased coils.

Open Coil

To make open coil innersprings, wire is fed through a coiler where steel is shaped into springs. The strands of springs are moved into an assembler where helical lacing is threaded through key parts of the springs to connect the coils and form a cassette. An operator then moves the spring core to a clipping station where a Leggett & Platt partner adds clips, often connecting a border rod. Once the open coil innerspring unit is complete, it is flat-packed for shipping.

View Open Coil ProductsFabric-Encased

To create ComfortCore® units, fabric is fed into the machine where the steel coils are inserted into partially formed pockets. Once a coil is placed inside, the pocket is ultrasonically welded and each spring is sealed inside an individual encasement. Coil strands are then fed into an assembler where a precision glue head applies adhesive to bond the strands together and form a full unit. Once the ComfortCore® unit is complete, it is roll-packed for shipping.

View ComfortCore Products

Making Innersprings

From steel to sleep, our company controls the entire process. Leggett & Platt owns North America’s largest electric furnace, located in Sterling, Illinois. There we melt scrap and transform the molten liquid into rod. Rod is drawn into wire. Our high-carbon wire is formed into a variety of gauges we can shape into unique coil designs.

1

STEEL

To make steel, Leggett & Platt begins by combining 98 parts iron and less than two parts carbon. Our team refines recipes that produce tough, formable wire. A strong and malleable piece of wire will feed through our world-class innerspring-making machines, retaining its durability.

Steel comes from iron ore and recycled scrap. Iron ore is mined, crushed, concentrated, made into pig iron, and then impurities are removed. Leggett & Platt’s recycled scrap, which is mainly comprised of automobiles, is separated, sized, mixed together, melted, and then refined.

To make steel, our metallurgists formulate a recipe and then add 95% recycled scrap steel to the largest electric furnace in North America. That steel recipe determines how the end product will turn out. We melt the scrap using an electrical arc created by passing a current through solid carbon electrodes. The material liquefies, then a technician checks its initial chemical composition and makes coarse adjustments.

Next, the molten steel is transferred into a ladle and then to a ladle-refining furnace where the temperature and chemicals are adjusted. Once those adjustments are made, we transfer the molten steel to the caster, where it’s poured into water-jacketed molds and allowed to solidify into squares about the size of a large man’s fist.

Each of these squares, called a billet, is about the same length as a Tyrannosaurus Rex.

Each of these squares, called billets, is about the same length as a Tyrannosaurus Rex. Once poured, billets are cooled for handling and transferred to the rolling mill. At the rolling mills, the billets are reheated, then pass through 27 sets of rolls to reduce the size, creating rod as small as 7/32 of an inch.

2

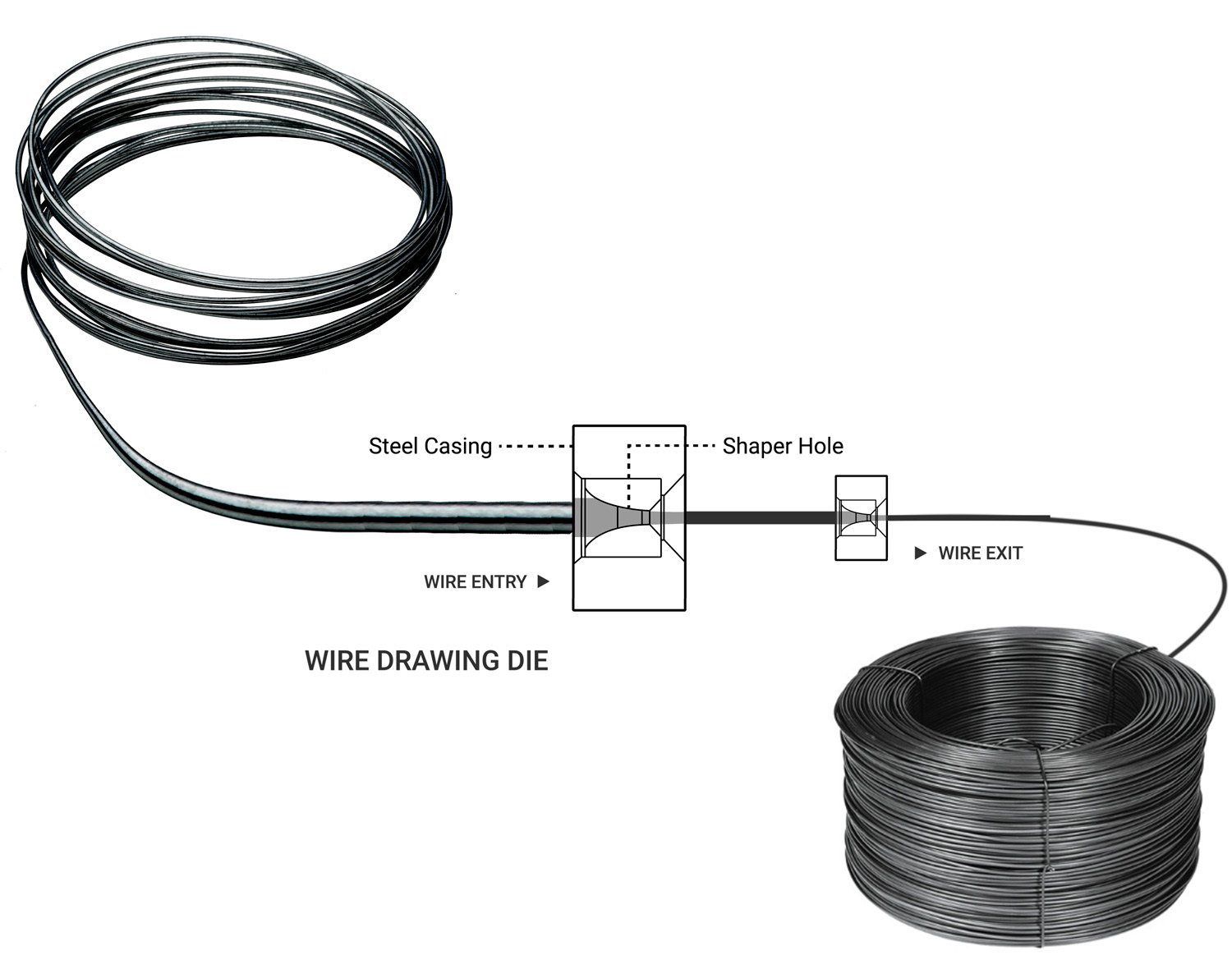

WIRE

Leggett & Platt controls every aspect of our innerspring-making process. It begins at Sterling Steel in Illinois, home to the largest electric furnace in North America. Each year we melt nearly a million tons of recycled scrap steel into billets. From there we make rod and draw it into wire at our own mills.

To make wire, we pull the steel rod through a series of steel-jacked, tungsten carbide wire-drawing dies. The first wire die is slightly smaller in diameter than the steel rod. Each subsequent die the wire is pulled through gets smaller and smaller, like nesting dolls, until finally we pull the wire through the die that creates its resting diameter. In addition to elongating and reducing the diameter, drawing the wire down creates a smooth, bright surface and increases wire’s hardness, tensile strength, and elastic limit.

Our heat-treated wire is malleable enough to take the shape of our designs, yet tough so it bounces back to its original shape night after night.

3

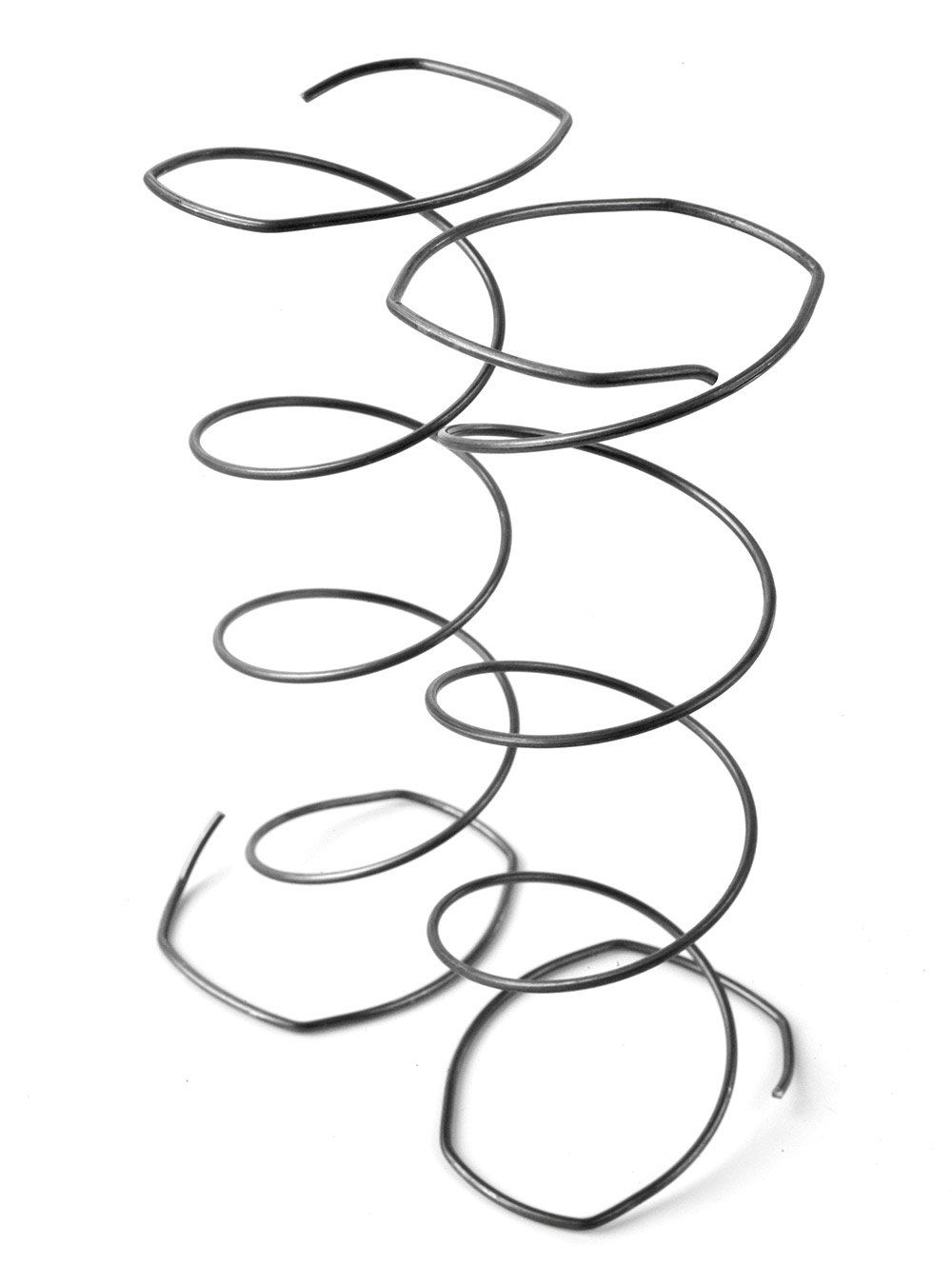

COILS

The steel wire used in Leggett & Platt’s high-quality innersprings makes each coil sturdy and resilient, even after years of use. Unlike imitators, our coils are tempered using heat or electricity so they bounce back to their original shape. After a coil is turned and shaped into its final form, tempering the spring realigns the molecular structure to ensure the coil won’t sag or settle.

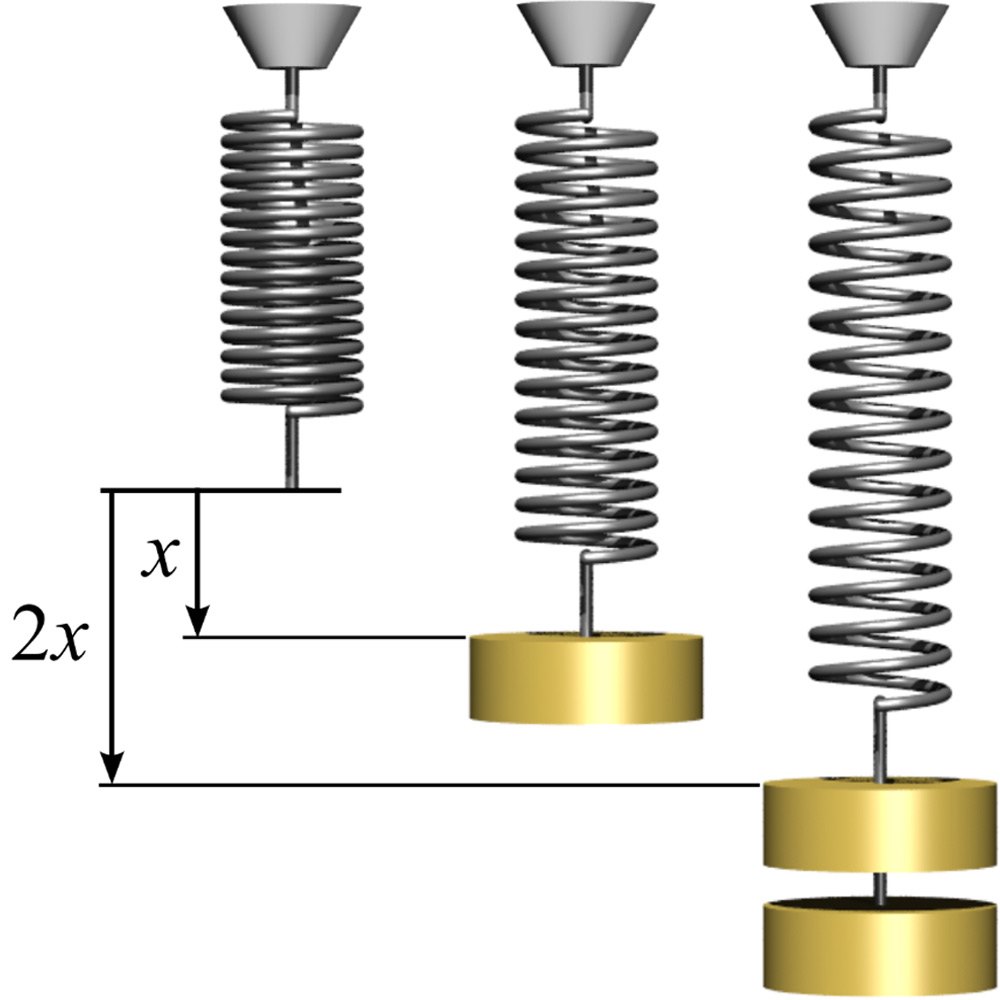

Since the inception of springs, Hooke’s Law has been the science behind supported sleep.

Hooke’s Law says a spring pushes back with the same force applied. Our engineers know how to use materials and engineering to take full advantage of Hooke’s Law, creating innersprings that place the body in a supported position, delivering proper spinal alignment and comfortable sleep.

Depending on a person’s weight, coils yield as weight is applied, creating an initial feeling of comfort with a feeling of support as the person’s body rides down into the unit. Different body types require unique levels of firmness and support to get the sleep they need. Engineering a variety of firmness and support characteristics is a process that can be controlled with changes to wire tensile, gauge, coil turns, and coil connecters.

Tensile Strength

Tensile strength is a wire’s capacity to stretch without breaking and its ability to withstand compression. At Leggett & Platt, we use high-tensile wire to create coils that are supportive and longer lasting than our competitor’s and those offering cheap imports. Testing data that proves our product’s superiority is available to customers.

Turns

If you take a straight piece of wire and create a turn, you will add a weak point. Turn that wire a few times and you’ll see a coil spring begin to form. The more turns, the softer the coil. A coil turn is defined as a complete rotation. Most coils have between five and eight turns. If you have two separate pieces of wire and their gauges are the same, a coil with a higher number of turns should be softer because each turn creates a point of weakness, making the coil easier to compress. Fewer turns means fewer weak points, resulting in a firmer coil.

Gauge

Wire gauges typically run from 12 to 19. A lower number corresponds to thicker wire. That means 12-gauge wire is fatter than 19-gauge. You can increase firmness by lowering the wire gauge. One way mattress makers can create a softer sleep surface is by using higher gauge wire, which is thinner and has more give. Units with thinner wire gauges are usually softer and springier.

Connections

For innerspring units using Bonnell and offset innersprings, the coils are connected using a helical lacing technique that involves a long spiral of high-gauge wire binding the rows together and bordering the entire unit. This method keeps the unit together while allowing the coils to move independently and conform to the shape of the body.